BioCNG System Overview

Simple and effective technology for cleaning and conditioning gas as a vehicle fuel

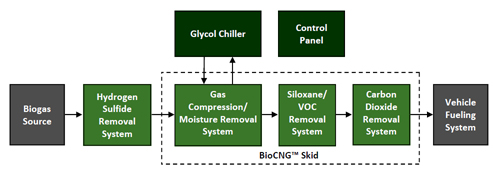

The BioCNG™ system offers a simple and effective technology for producing CNG vehicle fuel. Biogas is piped to the patented BioCNG™ System from a landfill or anaerobic digester. Then hydrogen sulfide, moisture, siloxanes, volatile organic compounds and carbon dioxide are removed. Product gas is piped to a vehicle fueling system for use as fuel in CNG vehicles.

BioCNG units are available in four standard sizes: BioCNG™ 50 BioCNG™ 100 BioCNG™ 200 and BioCNG™ 400. The model number refers to the amount of gas (in scfm) that each size uses:

If inlet biogas quality meets certain standards, BioCNG guarantees that the biogas produced meets SAE J1616 vehicle fuel quality standards. Production costs range from $0.65 to $1.15 for a gallon of gasoline equivalent (GGE), with the potential for renewable fuel credits (RIN).

The system can be supplemented or run in parallel with natural gas and it can be integrated with existing cogeneration systems. Vehicle fueling systems, (compression, storage, and fuel dispensers) can be customer-supplied or included with the BioCNG™ system.